Scale-up in Kenya

We first discovered sisal from our collaborator and long-time friend, Alex Odundo. Alex is based in Kisumu, Kenya and has dedicated his life to sisal - working with sisal farmers and building various tools to process sisal - turning these drought-resistant plants into useful commodities. Upon our success in developing absorbent fluff out of sisal, what better place to set-up shop to produce sisal-based pads other than Kenya?

We have spoken to both sisal farmers and local women in Kisumu and the answer to period poverty seems to already reside in Kenya — where sisal thrives and is already abundant!

Interview with local sisal farmers (left), interview with local women (right)

credit: Olex Techno Entreprises / Prakash Lab

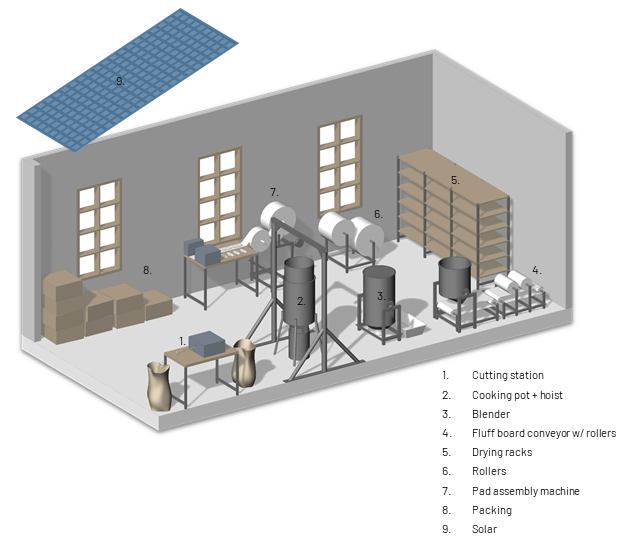

Can we transfer our knowledge and technology and train local workers to produce the first sisal-based pads in Kisumu, Kenya with the aim of 4,000 pads per day?

Proposed workshop

credit: Prakash Lab

Building pot and blender at Alex’s workshop (left), Pad-assembly area at the workshop (right)

credit: Olex Techno Entreprises / Prakash Lab

In order produce 4,000 pads per day, we’d need to process roughly 20kg of sisal fibers (~4g of fluff/pad). Aside from the drying step, one round of processing takes roughly 1-2 hours, so it’s feasible to conduct 4 rounds within an 8-hr work day. The pot and blender we designed and built has a capacity to process roughly 5kg of sisal fibers at a time.

The intended workshop would consist of several stations, including the cutting station, cooking area, blender, fluff board conveyor, drying racks, rollers, pad assembly, and packing areas, all powered by solar.

We replicated all the steps that we’ve tested in the lab, in the field (from cooking, blending, drying, fluffing, and finally assembling a pad). While some components/steps have been scaled up, some other parts are still in the works.

Can we reproduce the same fluff at scale in the field?

cooker + sieve being assembled (left), solution added to the pot (center), treated fibers (right);

credit: Olex Techno Entreprises / Prakash Lab

blender being tested (left), resulting sisal pulp (center), sisal pulp being pressed into fiber boards (right);

credit: Olex Techno Entreprises / Prakash Lab

fiber boards being dried (left), fiber board pulverized into fluff (center), fluff pressed into sheets (right);

credit: Olex Techno Entreprises / Prakash Lab

First sisal-based pad made in Kenya!

After a lot of efforts from all the team members, we’re happy to announce that we’ve produced the first sisal-based pad in Kenya! This pad is absorbent and fully compostable. Hopefully in the near future, we can get the pads tested and approved for use by Kenyan women!

How can we encourage locals to take part in this effort?

While in Kisumu, we also held a few pad-making workshops with the community and school to both share our research and process as well as encourage interested individuals to engage in this project. We look forward to continuing in this journey and it’s been an amazing experience to share this project with local Kenyans! The success of this project doesn’t reside within laboratory benches, but rather in the hands of those who will actively use this product in the field.

local students making a pad (left/right);

credit: Olex Techno Entreprises / Prakash Lab

locals attending the pad-making workshop and seeing the final product (left/right);

credit: Olex Techno Entreprises / Prakash Lab

Because sometimes, the answer isn’t found far away. Sometimes, it’s been growing right here all along."